Various

Eye safety

Eye safety is one of the critical topics for TOF cameras. The radiation of the illumination needs to be quite powerful to achieve a reasonable operating range. If the radiation is too strong, a hazard for the retina, the cornea or the skin can occur. The maximum radiance (W) or the maximum possible laser exposure in J/cmm2 is defined in the following standards:

- IEC-60825 for lasers

- IEC-62471 for LEDs

It is to note that eye safety has also to be obtained in case of a camera damage. E.g. if the current limiter of the illumination current is faulty, the maximum radiance must not be exceeded. Or if the lens or a diffuser in front of a laser is damaged or not present anymore due to a mechanical shock or due to an alteration of a user, the eye safety limits must be maintained. Typically, eye safety can easier be achieved with LEDs than with lasers.

Mechanical

A TOF camera should provide accurate 3D coordinates of objects in space. If the mechanical setup is not stable, position error is the result. The same occurs if the optical axis of the camera drifts with temperature.

EMC

A TOF camera emits high power radiation modulated at high frequency. The radiation is generated by high current modulated at high frequency. It’s obvious that the fast switching current (and voltage) emits radio frequency with harmonics into the GHz domain. Make the connections to the illumination a short a possible and shield them. Decouple the supply connections to the camera with filter chokes.

Functional safety

Many TOF cameras operate in safety critical missions. E.g. collision avoidance of a mobile robot, door safety device, car cabin monitoring, etc. It is the responsibility of the TOF camera manufacturer to fulfill the standards and regulations to achieve the required safety level. Typically, for safety applications, a certification by a notified body is required.

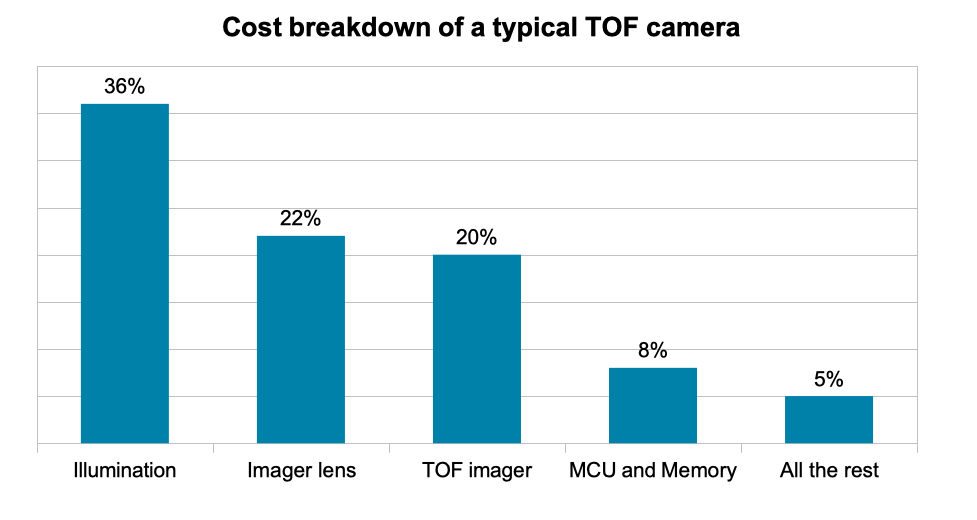

Cost

A look to typical bill of materials (BOM), the following list can be derived. Thus, the design of the illumination is, in terms of cost, the most important factor. Make sure that the camera illuminates only the area of interest. And, as much illumination as needed and not as much as possible.

Rules of thumb:

- Apply a risk analysis to identify the risks of the camera (FMEA)

- Talk to a notified body before you start the implementation

- Shield and filter the fast switching signals

- The imager lens shall be mechanically stable in relation to the fixation of the camera

- Focus on the cost driver number one, the illumination with is associated circuitry (driver and supply voltage generation)